Removing rust from a wood stove is essential for maintaining its functionality and aesthetic appeal while prolonging its lifespan. Over time, exposure to moisture and temperature changes can cause rust to develop on the surface of a wood stove, detracting from its appearance and potentially compromising its efficiency. However, effectively removing rust requires careful preparation and the use of appropriate techniques and materials.

From selecting the right rust removal products, such as wire brushes, sandpaper, or chemical rust removers, to following the correct procedures for cleaning and restoring the stove’s surface, there are several key considerations to keep in mind. In this comprehensive guide, we’ll explore step-by-step instructions, essential tips, and safety precautions for how to get rust off a wood stove, empowering homeowners and wood stove enthusiasts to restore their stoves to their former glory and enjoy efficient, reliable heating for years to come.

Importance of Maintaining a Rust-Free Wood Stove

Maintaining a rust-free wood stove is crucial for several reasons, encompassing safety, efficiency, and aesthetics. Rust can compromise the structural integrity of the stove, making it weaker and more susceptible to damage. This degradation can pose significant safety risks, especially if the stove’s weakened parts result in cracks or holes that allow harmful gases to escape into the living space.

Additionally, a rust-free stove operates more efficiently, ensuring that the heat produced is effectively radiated into the room rather than being absorbed by corroded metal. This improved efficiency can lead to better fuel economy and a warmer, more comfortable home. Moreover, a well-maintained, rust-free stove retains its visual appeal, adding to the overall ambiance of your living space.

Common Causes of Rust Formation

Understanding the common causes of rust formation on a wood stove is essential in preventing and addressing the issue effectively. One of the primary causes is exposure to moisture, which can occur from spills, high humidity, or leaks in the stove’s surroundings. When iron or steel in the stove comes into contact with water, it reacts with oxygen in the air to form iron oxide, commonly known as rust.

Additionally, temperature fluctuations can lead to condensation forming on the stove’s surface, especially in unheated or poorly ventilated spaces. Another contributing factor is the presence of corrosive substances, such as cleaning chemicals or ash residue, which can accelerate the rusting process if not properly cleaned off. Finally, environmental factors such as salt in coastal areas or pollutant deposits can also contribute to rust formation.

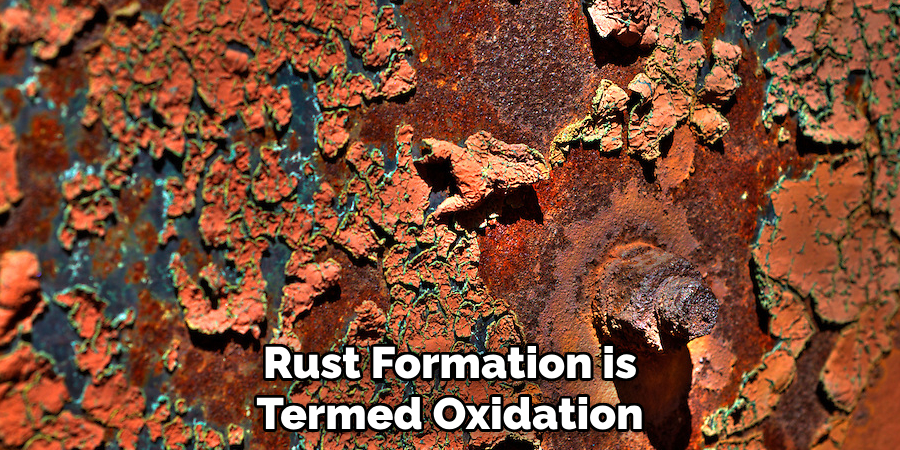

Understanding Rust Formation

Rust formation is a chemical process known as oxidation, where iron reacts with oxygen and moisture to produce iron oxide. This reaction is facilitated by the presence of water and occurs more rapidly in environments with high humidity or exposure to water sources. When iron or steel, which are the primary components of most wood stoves, come into prolonged contact with moisture, the electrons from the metal atoms bond with oxygen atoms, resulting in the reddish-brown compound we recognize as rust. Several factors can accelerate this process.

For instance, salt and other chemicals can act as catalysts, speeding up the rate of oxidation. This is particularly relevant in coastal areas where salt air can significantly enhance rusting. Likewise, pollutants such as sulfur dioxide and carbon dioxide in the air can combine with moisture to form acidic compounds, which further corrode the metal. Understanding these underlying mechanisms of rust formation allows homeowners to take informed preventative measures, such as using rust-resistant coatings, ensuring proper ventilation, and minimizing direct exposure to moisture and corrosive agents.

Chemical Process of Rust Formation on Metal Surfaces

The chemical process of rust formation on metal surfaces, primarily iron and steel, is a well-documented phenomenon termed oxidation. This process begins when the metal surface comes into contact with water and oxygen. Initially, the water molecules penetrate the metal’s microscopic crevices and react with the iron (Fe) atoms. This reaction facilitates the loss of electrons from the iron atoms, a process called oxidation, which produces iron ions (Fe²⁺).

These iron ions then interact with oxygen (O₂) from the air and further transform into iron oxide (Fe₂O₃), which manifests as the rust we observe. The presence of electrolytes, such as salt or acidic compounds, accelerates this reaction by enhancing the conductivity of the water, thus speeding up the electron transfer. Consequently, environments rich in salt or pollutants witness a more rapid rusting process. Understanding the intricacies of these chemical reactions underscores the importance of preventative measures, such as using protective coatings, to inhibit rust formation and ensure the longevity and functionality of metal surfaces.

Importance of Addressing Rust Promptly

Addressing rust promptly on your wood stove is imperative for maintaining its safety, efficiency, and longevity. When rust is allowed to develop unchecked, it can lead to severe structural damage, making the stove less stable and more prone to developing cracks or holes. This degradation can create hazardous conditions, especially if harmful gases are able to escape into your living space. Moreover, rust acts as an insulator that impairs the stove’s ability to efficiently radiate heat, leading to increased fuel consumption and uneven heating.

Prompt rust removal ensures optimal performance, helping your stove operate at peak efficiency and providing consistent warmth. Additionally, tackling rust early prevents it from spreading and causing more extensive damage, thereby reducing the need for costly repairs or complete replacement. By prioritizing timely rust management, homeowners can extend the life of their wood stoves, maintain a safe home environment, and enjoy better heating efficiency.

10 Methods How to Get Rust off a Wood Stove

Method 1: Assessing the Severity of the Rust

Before embarking on the rust removal process, it’s essential to assess the severity of the rust on your wood stove. Light surface rust may only require gentle cleaning and polishing, while deeper rust penetration may necessitate more aggressive techniques such as sanding or chemical treatments. Take the time to inspect the affected areas carefully, noting the extent of the rust and any areas of concern that may require special attention.

Method 2: Cleaning with Mild Soap and Water

For light surface rust and general cleaning, start by mixing a mild dish soap with warm water to create a gentle cleaning solution. Use a soft sponge or cloth to apply the solution to the rusted areas of the wood stove, gently scrubbing to loosen any dirt or debris. Rinse the stove thoroughly with clean water and dry it completely with a soft towel. This method helps remove surface contaminants and prepares the stove for further rust removal treatments.

Method 3: Removing Surface Rust with Steel Wool

For slightly more stubborn surface rust, steel wool can be an effective tool for removing rust without causing damage to the underlying metal surface. Choose a fine-grade steel wool, such as 000 or 0000, and lightly scrub the rusted areas of the wood stove in a circular motion. Take care not to apply too much pressure or scrub too aggressively, as this can scratch or gouge the metal surface. Once the rust has been removed, wipe the stove clean with a damp cloth to remove any residue.

Method 4: Sanding Away Deep Rust

For deeper rust penetration or more extensive rust damage, sanding may be necessary to restore the wood stove’s surface to its original condition. Start by selecting a fine-grit sandpaper, such as 220-grit or higher, and sand the rusted areas of the stove in a circular motion. Gradually increase the grit size as needed to achieve a smooth and even finish, taking care to blend the sanded areas with the surrounding metal surface. Once the rust has been removed, wipe the stove clean with a damp cloth to remove any sanding residue.

Method 5: Chemical Rust Removers

Chemical rust removers can be highly effective for removing stubborn rust from metal surfaces, including wood stoves. Choose a commercial rust remover product formulated specifically for use on metal surfaces, following the manufacturer’s instructions carefully. Apply the rust remover to the affected areas of the wood stove, allowing it to penetrate and dissolve the rust. Use a scrub brush or steel wool to agitate the surface and loosen any remaining rust particles. Rinse the stove thoroughly with water and dry it completely to prevent further rusting.

Method 6: Vinegar and Baking Soda Paste

An eco-friendly alternative to commercial rust removers is a paste made from vinegar and baking soda, which can effectively dissolve rust and restore the metal surface of a wood stove. Mix equal parts vinegar and baking soda to create a thick paste, then apply it to the rusted areas of the stove using a brush or sponge. Allow the paste to sit for several hours or overnight to penetrate the rust, then scrub the surface with a scrub brush or steel wool to remove the loosened rust particles. Rinse the stove thoroughly with water and dry it completely.

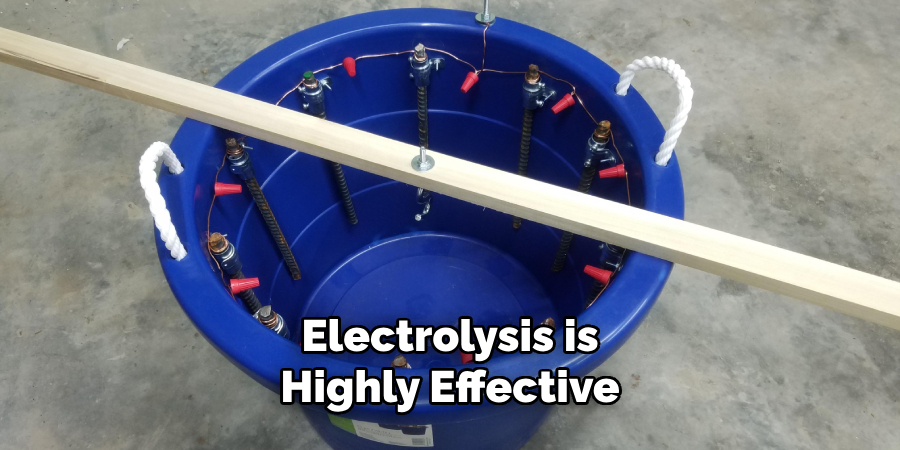

Method 7: Electrolysis Rust Removal

Electrolysis is a more advanced rust removal technique that utilizes an electrical current to break down rust and restore metal surfaces. While this method requires some additional equipment and setup, it can be highly effective for removing even the most stubborn rust from a wood stove. To perform electrolysis rust removal, you’ll need a container large enough to submerge the rusted parts of the stove, a power supply such as a battery charger, and a sacrificial anode made of a metal that won’t corrode, such as stainless steel.

Submerge the rusted parts of the stove in a solution of water and a rust-removing electrolyte, such as washing soda or sodium carbonate. Connect the positive terminal of the power supply to the sacrificial anode and the negative terminal to the rusted parts of the stove, then turn on the power supply to initiate the electrolysis process. Allow the electrolysis to proceed for several hours or overnight, periodically checking the progress and adjusting the setup as needed. Once the rust has been removed, remove the stove parts from the electrolyte solution, rinse them thoroughly with water, and dry them completely.

Method 8: Preventing Future Rust

Once you’ve successfully removed the rust from your wood stove, it’s essential to take steps to prevent future rusting and corrosion. Apply a protective coating of high-temperature paint or stove polish to the metal surfaces of the stove to create a barrier against moisture and oxidation.

Regularly inspect the stove for signs of rust or corrosion and address any issues promptly to prevent them from worsening. Additionally, avoid exposing the stove to excessive moisture or humidity, and store firewood and other combustible materials away from the stove to minimize the risk of rust formation.

Method 9: Polishing and Finishing

After removing rust from your wood stove, consider polishing and finishing the metal surfaces to enhance their appearance and durability. Use a metal polish or polishing compound to buff the stove’s surface to a high shine, following the manufacturer’s instructions for best results.

Alternatively, apply a protective coating of stove polish or wax to the metal surfaces to provide added protection against rust and corrosion. Take care to apply the polish or wax evenly and buff it to a smooth finish to achieve optimal results.

Method 10: Regular Maintenance and Care

Preventing rust on your wood stove requires regular maintenance and care to keep it in top condition. Clean the stove regularly to remove dirt, debris, and other contaminants that can contribute to rust formation. Inspect the stove for signs of rust or corrosion, paying special attention to areas prone to moisture buildup or high heat exposure.

Address any rust or corrosion issues promptly using the methods outlined above to prevent them from spreading or worsening over time. By incorporating regular maintenance and care into your routine, you can enjoy a rust-free wood stove for years to come.

Safety Precautions

Working with rust removal methods involves using tools, chemicals, and techniques that can pose certain risks if not handled properly. Here are some essential safety precautions to follow:

- Wear Protective Gear: Always wear gloves, safety goggles, and a mask to protect your skin, eyes, and respiratory system from abrasive particles, chemicals, and dust.

- Ventilation: Ensure that the area where you are working is well-ventilated, especially when using chemical rust removers or when sanding. Proper ventilation helps to dissipate fumes and dust, reducing the risk of inhalation and flammability.

- Read Product Instructions: Always read and follow the manufacturer’s instructions and warning labels on any rust removal products or equipment you use. Incorrect use of chemicals or tools can lead to accidents or ineffective results.

- Proper Disposal: Dispose of any used sandpaper, rags, and chemical residues according to local regulations. Improper disposal can harm the environment and pose health risks.

- Fire Safety: Be cautious when working with electrical equipment such as power sanders and during the electrolysis rust removal process. Keep a fire extinguisher nearby and avoid working near flammable materials.

- Avoid Direct Skin Contact: Prolonged skin contact with rusted metal, chemicals, or abrasive materials can cause irritation or allergic reactions. Wash your hands thoroughly after handling any of these materials.

- First Aid Kit: Have a first aid kit readily available in case of any minor cuts, burns, or chemical exposures during the rust removal process.

- Surface Stability: Ensure that the wood stove is stable and securely positioned before starting rust removal procedures. An unstable surface can lead to accidents and injuries.

By adhering to these safety precautions, you can effectively and safely remove rust from your wood stove, ensuring a secure and successful restoration process.

Assessing the Extent of Rust Damage

Before beginning the rust removal process, it is crucial to thoroughly assess the extent of rust damage on your wood stove. Start by visually inspecting the entire surface of the stove, looking for areas where the paint or finish has flaked off, revealing rusted metal underneath. Pay close attention to sections that are more prone to moisture accumulation or heat exposure, such as the bottom edges, seams, and around the door and chimney.

Use a flashlight to enhance your visibility, especially when examining the interior parts of the stove. For a more detailed assessment, gently scrape the rusted areas with a metal brush or scraper to determine how deep the rust has penetrated. Superficial rust can be identified by its flaky and powdery texture, which can usually be removed with light sanding or chemical treatments. In contrast, more severe corrosion, signified by pitting or holes in the metal, may require extensive repair or replacement.

Conclusion

Removing rust from a wood stove is a labor-intensive process that requires patience, diligence, and the right techniques. By following the ten elaborated methods outlined above, you can effectively restore your wood stove’s metal surfaces to their original condition and prevent future rusting and corrosion.

Whether you opt for gentle cleaning methods, aggressive rust removal techniques, or eco-friendly alternatives, each approach offers unique benefits and considerations for achieving optimal results. Hopefully, this article gave you some helpful tips about how to get rust off a wood stove successfully, so now that you have the proper knowledge on how to get the job done, why not give it a try today?

About the Author

Adrian Green, a lifelong woodworking enthusiast, shares his passion for the craft through The Woodenify Blog. With a foundation built on years of hands-on experience in his father’s woodworking shop, Adrian is dedicated to helping others learn and grow in the world of DIY woodworking. His approach to woodworking combines creativity, practicality, and a deep appreciation for the art of building with your own hands. Through his blog, he inspires individuals of all skill levels to embark on their own woodworking journeys, creating beautiful, functional pieces of furniture and décor.

Professional Focus

- Specializes in DIY woodworking projects, from furniture to home décor.

- Provides step-by-step guides and practical tutorials for woodworkers of all skill levels.

- Dedicated to helping readers build confidence and skill through easy-to-follow instructions and tips.

- Passionate about fostering a community of makers who can share, learn, and grow together.

Education History

- University of Craft and Design – Bachelor of Fine Arts (BFA) in Woodworking and Furniture Design

- Woodworking Apprenticeships – Extensive hands-on training with skilled craftsmen to refine carpentry and furniture making techniques.

- Online Courses & Masterclasses – Continued education in advanced woodworking techniques, design principles, and specialized tools

Expertise:

- DIY woodworking, carpentry, furniture making, and home décor projects.

- Creating accessible tutorials and guides for beginner to advanced woodworkers.

- Sharing the joys and satisfaction of woodworking, from raw materials to finished products.