Plywood warping is a common challenge in DIY projects and professional construction, significantly compromising the final product’s structural integrity and aesthetic appeal. Several factors, including moisture absorption, uneven drying, and improper storage, influence the tendency of plywood to warp. This phenomenon affects the material’s flatness and can lead to long-term durability issues, making it essential to understand how to keep plywood from warping.

Maintaining flat and stable plywood surfaces is crucial for the longevity and success of any construction or crafting endeavor. This guide will equip you with proven strategies and techniques for preventing plywood warping, ensuring your projects remain strong, durable, and visually pleasing. Through a step-by-step approach, we will explore everything from selecting the right plywood to proper installation and maintenance practices designed to combat warping and preserve the quality of your plywood surfaces.

Selecting High-Quality Plywood

One of the initial steps in ensuring your plywood does not succumb to warping is selecting high-quality plywood. This selection process fundamentally revolves around understanding plywood grades, opting for exterior-grade plywood, and meticulously inspecting for any defects prior to purchase.

A. Understanding Plywood Grades

Plywood grades are determined based on the quality of the veneer surfaces and the number of defects within the sheet. These grades range from A, which denotes a smooth and paintable surface, down to D, which may have knots and visible defects. For projects where the stability and appearance of the plywood are paramount, A or B grade sheets are recommended. These higher-grade sheets have fewer imperfections, making them less prone to warping due to an even distribution of moisture and stresses across the sheet.

B. Choosing Exterior-Grade Plywood

Exterior-grade plywood, distinguished by its waterproof glue bonding the layers, offers enhanced durability and resistance to moisture compared to interior-grade plywood. This quality makes it a superior choice for outdoor projects or in areas of high humidity, significantly reducing the risk of warping. When selecting plywood for any application that might expose the wood to moisture, opting for an exterior grade is a proactive step in preventing warping.

C. Inspecting for Defects

Before purchasing plywood, a thorough inspection for any defects is crucial. Look for sheets that are free from knots, splits, or signs of delamination, as these imperfections can compromise the integrity of the plywood and increase its susceptibility to warping. Pay particular attention to the edges and corners, ensuring no damages might affect the plywood’s performance. Taking the time to select defect-free plywood not only aids in preventing warping but also contributes to your project’s overall success and longevity.

How to Keep Plywood from Warping: Proper Storage and Handling

Proper storage and handling of plywood are critical steps in preventing warping and ensuring the material’s longevity. Adopting correct storage practices can significantly minimize the risk of moisture absorption, mold growth, and the detrimental effects of temperature fluctuations on plywood sheets.

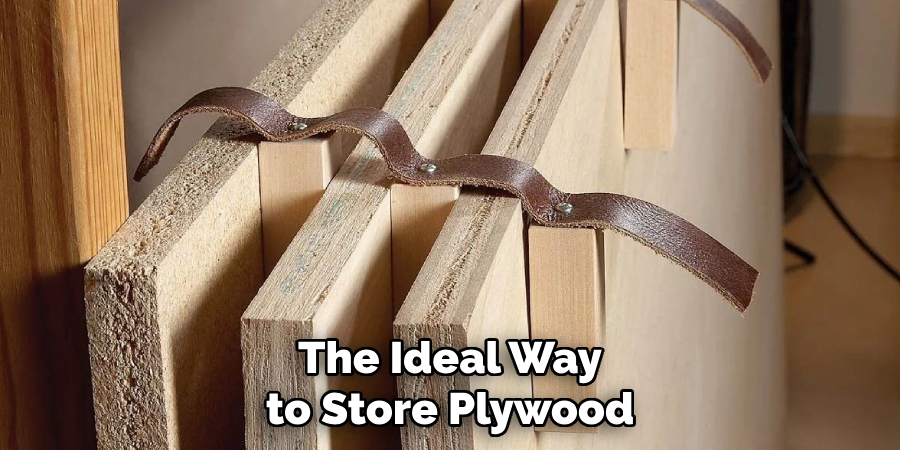

A. Storing Flat and Elevated

The ideal way to store plywood is by laying the sheets flat on a level surface. This position helps distribute the weight evenly across the sheet, preventing the formation of bows or bends that lead to warping. Elevating plywood sheets off the ground is equally crucial. Utilizing pallets or racks for elevation ensures that the plywood does not come into direct contact with moisture on the floor, which is a common cause of warping. This practice is particularly important in areas prone to dampness or flooding.

B. Providing Air Circulation

Adequate air circulation around stored plywood sheets is essential to prevent moisture buildup and the potential growth of mold and mildew, which can weaken the plywood and increase the risk of warping. Ensure there is sufficient space between stacked sheets and around the perimeter of the stored plywood to allow air to flow freely. This can be achieved by using stickers (small strips of wood) placed between each sheet, facilitating air circulation and aiding in the even drying of the materials.

C. Avoiding Direct Sunlight

Exposure to direct sunlight and extreme temperature fluctuations can significantly impact the moisture content of plywood, increasing the risk of warping. It is advisable to store plywood sheets in a cool, dry place away from windows or doors where they might be exposed to direct sunlight. Additionally, avoiding areas with significant temperature swings, such as near heating vents or air conditioning units,

How to Keep Plywood from Warping: Sealing and Coating

Sealing and coating are paramount in ensuring plywood’s long-term durability and stability by protecting it against moisture infiltration and environmental damage. This section will provide a detailed walkthrough on applying sealant or primer, adding a moisture barrier, and conducting regular maintenance to uphold the integrity of your plywood projects.

A. Applying Sealant or Primer

Applying a quality sealant or primer is the primary line of defense in safeguarding plywood from warping. This process involves thoroughly coating all sides and edges of the plywood sheets to seal the pores and significantly minimize moisture absorption. Choosing a sealant or primer designed for exterior use is imperative to ensure optimal protection against humidity and moisture. The application should be done in a well-ventilated area, following the manufacturer’s instructions for drying times between coats. By sealing every part of the plywood, including the often-neglected edges, you create a moisture-resistant barrier that enhances the plywood’s resilience to warping and environmental stresses.

B. Adding Moisture Barrier

After applying a sealant or primer, adding an additional moisture barrier, such as paint or varnish, provides an extra layer of protection against moisture infiltration. These coatings shield the plywood from moisture and UV rays, temperature fluctuations, and other environmental factors that could lead to deterioration.

When selecting a moisture barrier, opting for products specifically formulated for outdoor use is crucial if the plywood will be exposed to the elements. Apply the moisture barrier evenly across the surface, following the wood grain, and allow sufficient drying time as specified by the product instructions. This step not only preserves the structural integrity of the plywood but also enhances its aesthetic appearance.

C. Regular Maintenance

Regular maintenance is essential to ensure the long-term stability and appearance of plywood. This involves periodically inspecting the plywood surfaces for any signs of wear and tear, such as cracking, peeling, or discoloration of the sealant, primer, or moisture barrier. If any damage is observed, a refinishing process should be done promptly to restore the protective coatings. Refinishing may include sanding down the damaged area, cleaning it thoroughly, and reapplying the necessary sealants and moisture barriers. Maintaining a consistent maintenance schedule can significantly extend the life of your plywood projects, ensuring they remain strong, durable, and visually pleasing for many years.

By diligently following the steps outlined in this section, you can effectively prevent plywood from warping, ensuring the longevity and success of your construction or crafting endeavors.

How to Keep Plywood from Warping: Proper Installation Techniques

Proper installation techniques are vital to prevent warping and ensure the optimal performance of plywood in construction projects. Understanding and applying the right methods during the installation process can significantly extend the lifespan and maintain the structural integrity of your plywood. This section will cover essential practices such as allowing for expansion, using correct fasteners, and avoiding overlapping joints.

A. Allowing for Expansion

Wood is a natural material that expands and contracts in response to changes in humidity and temperature. To accommodate this natural movement and prevent potential warping or cracking, adequate expansion gaps between plywood sheets and surrounding structures are crucial. A general rule of thumb is to leave a gap of at least 1/8 inch between sheets and other elements. This space allows the plywood to expand and contract without pushing against adjacent materials, which could lead to deformation or damage.

B. Using Correct Fasteners

The choice of fasteners plays a significant role in the stability and longevity of plywood installations. Using proper fasteners such as screws or nails with adequate holding power is essential to secure plywood sheets firmly while allowing for natural wood movement. It is advisable to use screws designed for wood, which offer better grip and withdrawal resistance than nails. The spacing of fasteners should be carefully planned, usually 6-8 inches apart along the edges and 12 inches in the field of the sheet, to distribute the load evenly and prevent overloading any single point, which might induce stress and lead to warping.

C. Avoiding Overlapping Joints

When installing plywood, it is essential to ensure that the joints between sheets do not overlap or align directly with joints in underlying layers or adjoining materials. Overlapping or directly aligned joints can create stress concentrations, weakening the structural integrity of the installation and increasing the risk of warping. Staggering the joints, much like laying bricks, can distribute stress more evenly and contribute to the overall strength and stability of the structure. This practice is particularly important in flooring and roofing applications, where the uniform distribution of loads is crucial to prevent deformation.

Adhering to these proper installation techniques can effectively minimize the risk of warping and ensure your plywood projects are durable, stable, and aesthetically pleasing. Incorporating these practices into your installation will pave the way for successful and long-lasting construction and crafting projects.

Reinforcement and Support

Ensuring plywood’s structural integrity and longevity in construction and crafting projects often necessitates additional reinforcement and support measures. This chapter will discuss effective strategies such as installing backer boards or braces, using structural reinforcements, and the importance of regular inspections to maintain plywood’s durability and appearance.

A. Adding Backer Boards

Installing backer boards or braces behind plywood sheets is a practical approach to providing additional support and preventing flexing, especially in applications requiring a flat, stable surface, such as wall paneling or cabinetry. Backer boards, made from materials like fiber cement or gypsum, offer a rigid backing that helps to distribute weight evenly across the plywood, reducing the likelihood of bending or warping. The installation process involves securing the backer boards directly to the studs or frames before attaching the plywood, ensuring a solid and stable foundation for any project.

B. Using Structural Reinforcements

Incorporating structural reinforcements such as beams or joists is crucial in applications where plywood, such as flooring or roofing, will bear significant weight. These reinforcements help distribute the load across a broader area, reducing stress on any point of the plywood and minimizing the risk of sagging and warping. The key is to design the framework with adequate spacing between beams or joists according to the specific requirements of the project and the expected load, ensuring the plywood remains flat and stable under pressure.

C. Regular Inspections

Periodical inspections of plywood surfaces play an integral role in the maintenance and longevity of plywood projects. These inspections should focus on identifying any signs of warping, moisture damage, or structural weaknesses that could compromise the integrity of the plywood. Upon detecting issues, prompt action is necessary to address the underlying causes, which may involve repairs such as replacing affected sections, reinforcing the structure, or reapplying sealants and moisture barriers. Establishing a regular inspection and maintenance schedule can significantly prolong the life of plywood installations, ensuring they remain strong and visually appealing over time.

By implementing these reinforcement and support strategies, individuals and professionals can significantly enhance the performance and lifespan of plywood in various applications. From the strategic installation of backer boards to incorporating structural reinforcements and conducting regular inspections, each measure contributes to the overall stability and durability of plywood projects.

Proper Ventilation and Climate Control

Proper ventilation and climate control are critical factors in maintaining the integrity and appearance of plywood in construction and crafting projects. Without adequate ventilation, enclosed spaces can become hotbeds for humidity buildup and moisture retention, which can adversely affect plywood surfaces. Maintaining stable indoor temperature and humidity levels is essential to minimize wood movement and prevent warping. This chapter will explore effective strategies for ensuring proper ventilation, controlling indoor climate, and utilizing dehumidifiers or humidifiers to protect plywood surfaces.

A. Ensuring Proper Ventilation

Providing adequate ventilation in enclosed spaces is vital to prevent humidity buildup and moisture retention around plywood surfaces. Natural ventilation can be achieved through the strategic placement of windows, doors, and vents that allow air to circulate freely, removing excess moisture from the air. In areas where natural ventilation is insufficient, mechanical ventilation systems, such as exhaust fans and air vents, should be installed to actively remove moist air from inside buildings. Proper ventilation not only aids in regulating moisture levels but also contributes to a healthier indoor environment by reducing the risk of mold and mildew growth that could potentially harm plywood surfaces.

B. Controlling Indoor Climate

Maintaining stable indoor temperature and humidity levels is crucial for minimizing wood movement and preventing the warping of plywood. Fluctuations in temperature and humidity can cause plywood to expand and contract, potentially leading to structural issues over time. To avoid such problems, it is recommended to use climate control systems, such as air conditioning and heating, to keep the indoor environment within a consistent range. Ideally, humidity levels should be maintained between 30% and 50% to prevent excess wood movement. Regular monitoring with a hygrometer can help in adjusting the settings of climate control systems to ensure optimal conditions are consistently maintained.

C. Using Dehumidifiers or Humidifiers

In regions where indoor humidity levels tend to rise above or fall below the recommended range, dehumidifiers or humidifiers can effectively control moisture levels and protect plywood surfaces. Dehumidifiers can be utilized in humid environments to extract excess moisture from the air, preventing it from settling on plywood surfaces and causing swelling or mold growth. Conversely, humidifiers can add moisture to the air in dry climates to prevent plywood from drying out and cracking. Selecting the proper device based on the specific needs of the indoor environment ensures that plywood remains in optimal condition, free from the adverse effects of excessive or insufficient humidity.

Implementing these ventilation and climate control strategies can significantly enhance the longevity and aesthetic quality of plywood in construction and crafting projects. Proper ventilation, stable indoor climate control, and the judicious use of dehumidifiers or humidifiers, when needed, are all essential measures in protecting plywood surfaces from the damaging effects of moisture and temperature fluctuations.

Conclusion

This document has detailed critical strategies to prevent plywood from warping, including choosing the right grade, ensuring it is properly acclimatized, applying surface treatments, and reinforcing structures for additional support. Regular maintenance and inspections are pivotal in identifying and mitigating potential issues before they escalate.

Proactive prevention measures and diligent maintenance are indispensable for maintaining flat and stable plywood surfaces over time. Adequate ventilation, climate control, and humidity management strategies are also crucial. These efforts collectively serve as the foundation for “how to keep plywood from warping,” ensuring the integrity and appeal of plywood in a multitude of applications.

Adherence to these prescribed strategies and measures prevents warping and instills a sense of satisfaction in achieving long-term durability and performance of plywood projects. By dedicating the necessary care and attention to detail, stakeholders can ensure their plywood remains resilient, functional, and visually pleasing for years to come.

About the Author

Adrian Green, a lifelong woodworking enthusiast, shares his passion for the craft through The Woodenify Blog. With a foundation built on years of hands-on experience in his father’s woodworking shop, Adrian is dedicated to helping others learn and grow in the world of DIY woodworking. His approach to woodworking combines creativity, practicality, and a deep appreciation for the art of building with your own hands. Through his blog, he inspires individuals of all skill levels to embark on their own woodworking journeys, creating beautiful, functional pieces of furniture and décor.

Professional Focus

- Specializes in DIY woodworking projects, from furniture to home décor.

- Provides step-by-step guides and practical tutorials for woodworkers of all skill levels.

- Dedicated to helping readers build confidence and skill through easy-to-follow instructions and tips.

- Passionate about fostering a community of makers who can share, learn, and grow together.

Education History

- University of Craft and Design – Bachelor of Fine Arts (BFA) in Woodworking and Furniture Design

- Woodworking Apprenticeships – Extensive hands-on training with skilled craftsmen to refine carpentry and furniture making techniques.

- Online Courses & Masterclasses – Continued education in advanced woodworking techniques, design principles, and specialized tools

Expertise:

- DIY woodworking, carpentry, furniture making, and home décor projects.

- Creating accessible tutorials and guides for beginner to advanced woodworkers.

- Sharing the joys and satisfaction of woodworking, from raw materials to finished products.