Creating smooth and effortless movement between wood surfaces is essential for various woodworking projects, furniture construction, and home renovations. Learning how to make wood slide on wood is crucial for ensuring ease of operation in drawers, cabinets, sliding doors, and other wooden components. In this article, we’ll explore practical methods and techniques for achieving smooth wood-on-wood sliding action.

From selecting the right lubricants and finishes to optimizing surface preparation and joint design, we’ll provide comprehensive insights to help you achieve frictionless movement between wooden surfaces. Whether you’re a seasoned woodworker or a DIY enthusiast tackling your first project, mastering the art of making wood slide on wood will enhance the functionality, durability, and overall quality of your woodworking endeavors. Join us as we unlock the secrets to effortless wood-on-wood sliding and elevate the craftsmanship of your creations to new heights.

Importance of Making Wood Slide on Wood

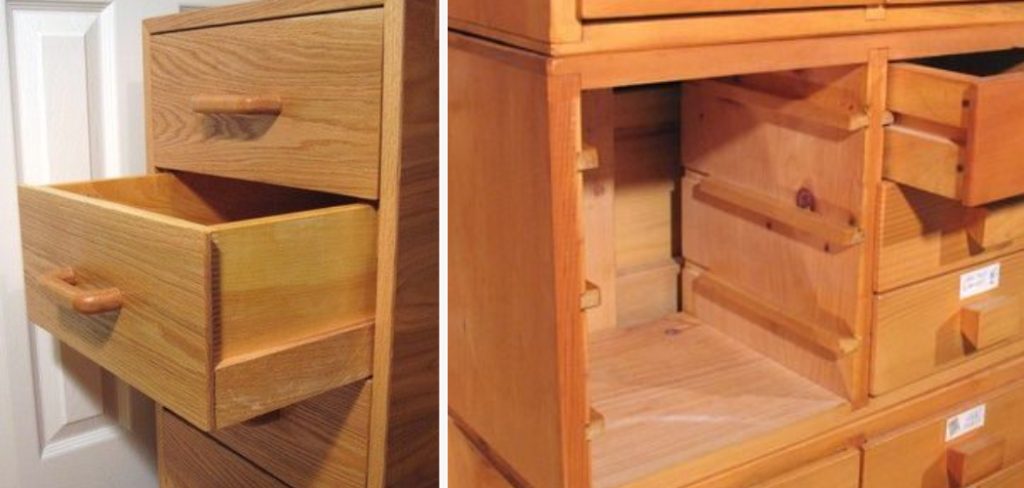

The significance of ensuring a smooth wood-on-wood glide cannot be overstated. Apart from reducing wear and tear on both surfaces, it significantly enhances the user experience by allowing for seamless operation of drawers, cabinets, and other household fixtures.

A wood surface that effortlessly slides against another adds to the functionality and aesthetic appeal, making everyday interactions more satisfying. In the context of craftsmanship, the ability to execute this skill effectively can set a project apart, defining a craftsman’s attention to detail and dedication to quality. Furthermore, minimizing friction not only extends the lifespan of wooden components but also reduces the need for repairs and maintenance, offering long-term value and satisfaction.

Understanding Wood Friction

Before we can master the art of making wood slide smoothly on wood, it’s crucial to grasp the concept of wood friction. Friction between wood surfaces is the resistance encountered when one piece of wood moves over another. This resistance is influenced by factors such as the type of wood, surface finish, and the presence of any contaminants or debris between the surfaces.

Softwoods tend to generate more friction than hardwoods due to their softer and sometimes sticky sap residue, which can increase surface resistance. Surface finish plays a significant role as well; unfinished or rough wood surfaces create more friction compared to those that are finely sanded or coated. Understanding these factors is the first step toward reducing friction and achieving a smooth sliding action in your woodworking projects.

Reducing Friction Between Wood Surfaces

To effectively reduce friction between wood surfaces and achieve a smooth sliding motion, several strategies can be employed. Firstly, selecting the right type of wood is critical. Hardwoods, with their dense and smooth grain, generally provide less resistance than softwoods. For the surfaces that will be in contact, ensuring they are as smooth as possible is paramount.

This can involve careful sanding with progressively finer grits of sandpaper, which minimizes scratches and imperfections that can catch and cause friction. Additionally, applying the appropriate finish, such as wax, varnish, or polyurethane, can create a slick barrier that promotes easier sliding.

Sometimes, the use of specialized lubricants designed for wood-on-wood applications can provide a temporary solution, although the long-term application of these products requires careful consideration to avoid attracting dust and grime, which can increase friction over time. By understanding and applying these techniques, the reduction of wood-on-wood friction is achievable, leading to the enhanced performance and longevity of wooden components in various projects.

Importance of Reducing Friction for Smooth Sliding

Reducing friction between wood surfaces is not just about achieving smooth movement; it’s fundamental to the longevity and preservation of the wood itself. Friction leads to wear – and in woodworking projects, this wear can manifest as rough edges, degradation of the wood’s surface, and ultimately, the weakening of the wooden structure over time.

When wood slides smoothly against wood, the risk of these deleterious effects diminishes significantly. This preservation of the wood’s integrity is especially crucial in applications where the wood surfaces are subjected to frequent movement, such as drawers and sliding doors. By focusing on minimizing friction, woodworkers and DIY enthusiasts can ensure that their creations not only operate smoothly but also stand the test of time, maintaining their beauty and functional utility for many years.

Characteristics of Wood Species Suitable for Sliding

Certain characteristics of wood species make them more suitable for projects requiring smooth sliding surfaces. Hardwoods, for example, are typically more desirable for their density and smooth grain, which contribute to lower friction and enhanced durability. Species like maple, cherry, and walnut are favored for their dense grain structure, providing a smooth glide when properly finished.

Additionally, these woods have a natural resilience to wear, making them ideal for high-use applications such as drawer slides and furniture parts. On the other hand, some softwoods, despite their higher friction tendency, can be suitable if treated and finished correctly. Cedar and pine, when finely sanded and sealed, can offer a cost-effective alternative for projects where hardwoods might be impractical. The crucial factor in selecting a wood species for sliding applications is understanding the balance between the wood’s natural properties, its intended use, and the project budget.

10 Methods How to Make Wood Slide on Wood

1.Select the Right Wood Species:

Choosing the appropriate wood species is crucial for achieving smooth wood-on-wood sliding action. Opt for hardwoods such as maple, cherry, or oak, known for their dense and durable characteristics. These hardwoods have tight grain patterns and smooth textures that facilitate smoother sliding compared to softer woods like pine or cedar. Additionally, hardwoods are less likely to warp or split, ensuring longevity and stability for your project.

In addition to considering the species of wood, it’s important to also think about the specific cut of the wood. Quarter-sawn wood is a popular choice for woodworking projects that require sliding action. This type of cut creates a more stable grain pattern and reduces the likelihood of warping or twisting over time.

Another factor to consider is the moisture content of the wood. Wood with a higher moisture content may shrink, expand, or warp more easily when exposed to changes in humidity and temperature. It’s important to select wood that has been properly dried and cured for optimal stability.

2.Surface Preparation:

Proper surface preparation is essential for reducing friction and promoting smooth sliding between wood surfaces. Begin by sanding the wood surfaces thoroughly to remove any rough spots, imperfections, or splinters. Use progressively finer grit sandpaper to achieve a smooth and even surface, paying close attention to the edges and corners where friction is most likely to occur. Wipe down the surfaces with a clean cloth to remove any dust or debris before proceeding to the next step.

Once the surfaces are smooth and free of imperfections, it is important to apply a lubricant or protective coating. This not only reduces friction but also helps prevent damage and wear on the wood surfaces. There are various options for lubricants, such as wax, oil, or silicone-based sprays. It is important to choose a product that is suitable for wood surfaces and does not leave a residue or build-up.

In addition to lubricants, another method for reducing friction between wood surfaces is using specialty glides or pads. These can be attached to the bottom of furniture legs or other wooden objects that come into contact with each other. They create a smooth and slippery surface, allowing for easy sliding without causing damage to the wood.

3.Apply Lubricants:

Lubricants play a crucial role in reducing friction and facilitating smooth sliding between wood surfaces. Various lubricants can be used for this purpose, including wax-based products, silicone sprays, and dry lubricants. Apply the lubricant generously to the contacting surfaces, ensuring even coverage, and reapply as needed to maintain smooth sliding action over time. Additionally, make sure to clean any excess lubricant off the surface after application to prevent unwanted build-up.

In addition to lubricants, there are other methods that can be used to reduce friction between wood surfaces. One such method is sanding down the rough edges or using sandpaper to smooth out any imperfections on the surface. This not only helps in reducing friction but also improves the overall appearance of the wood.

4.Use Drawer Slides or Glides:

Incorporating drawer slides or glides into furniture designs is an effective way to achieve smooth and reliable wood-on-wood sliding action. Drawer slides are mechanical hardware components that allow drawers to slide in and out effortlessly. Choose high-quality drawer slides made from materials like steel or ball-bearing construction for optimal performance and durability. Drawer slides come in a variety of styles, including side-mount, under-mount, and center mount. They can also be categorized into three types: roller slides, ball-bearing slides, and dovetail slides.

Roller slides are the most basic type of drawer slide and use plastic rollers or wheels to provide smooth movement. They are an affordable option and work best for light-duty applications. Ball-bearing slides, on the other hand, use steel ball bearings to provide smooth and quiet operation. They come in a range of weight capacities and are perfect for medium- to heavy-duty applications. Lastly, dovetail slides use interlocking wedge-shaped pieces to create a durable and stable sliding mechanism. They are ideal for heavy loads and high-traffic areas.

5.Install Nylon or Teflon Glides:

Nylon or Teflon glides are another option for promoting smooth sliding between wood surfaces. These self-adhesive or screw-on glides feature low-friction surfaces that reduce wear and tear and minimize noise. Install nylon or Teflon glides on the bottom of drawers, cabinet doors, or other wooden components to facilitate smooth movement and prevent scratching or damage to the wood surfaces. These glides are easy to install and come in a variety of sizes to fit any wooden surface.

Nylon glides are made from polyamide, also known as nylon. This synthetic material is strong, durable, and resistant to abrasion, making it an excellent choice for furniture glides. Teflon glides, on the other hand, are made from polytetrafluoroethylene (PTFE), a synthetic polymer that is also known as Teflon. PTFE is well-known for its non-stick properties and low coefficient of friction, making it an ideal material for glides.

In addition to being easy to install and offering smooth sliding, nylon and Teflon glides also have the added benefit of being moisture-resistant. This makes them suitable for use in humid or wet environments, such as kitchens and bathrooms. They are also resistant to chemicals, oils, and solvents, making them a long-lasting solution for your furniture gliding needs.

6.Apply Furniture Wax:

Furniture wax is a traditional and time-tested method for promoting smooth wood-on-wood sliding action. Apply a thin layer of furniture wax to the contacting surfaces using a clean cloth or brush. Buff the waxed surfaces with a soft cloth to achieve a smooth and glossy finish. Furniture wax not only reduces friction but also protects the wood from moisture and wear over time. Additionally, it can also fill in small cracks and scratches, providing a more polished appearance.

To achieve the best results, it is recommended to use high-quality furniture wax that contains natural ingredients such as beeswax or carnauba wax. These natural waxes offer superior protection and enhance the beauty of the wood without leaving behind any harmful chemicals.

Before applying furniture wax, make sure to clean the surfaces thoroughly and remove any dust or debris. This will ensure that the wax adheres properly to the wood and provides an even finish.

7.Optimize Joint Design:

The design of joints between wood surfaces can significantly impact sliding action and overall functionality. Choose joint designs that minimize friction and provide adequate clearance for smooth movement. Bevel edges, chamfer corners, or round over sharp edges to reduce contact points and promote smoother sliding between wood surfaces.

In addition to promoting smoother sliding, optimizing joint design can also improve the overall strength and durability of wooden structures. By minimizing friction and providing adequate clearance, stress on joints is reduced, resulting in a longer lifespan for the structure.

8.Maintain Proper Alignment:

Proper alignment is critical for achieving smooth wood-on-wood sliding action, particularly in sliding doors, drawers, or cabinet components. Ensure that the wood surfaces are aligned correctly and parallel to each other to prevent binding or sticking. Use shims or spacers to adjust the alignment as needed and maintain consistent clearance between the sliding surfaces. Make sure to check the alignment regularly and make adjustments as necessary.

In addition to aligning wood surfaces, proper alignment is also essential for door and drawer hardware installation. When installing hinges or slides, it’s crucial to keep them aligned with each other and the rest of the cabinet. Misaligned hardware can cause doors and drawers to sag or not close properly, leading to premature wear and malfunction. Use a level or straight edge to ensure proper alignment before securing hardware in place.

9.Apply Dry Lubricant Sprays:

Dry lubricant sprays are specially formulated to reduce friction and provide long-lasting smooth sliding action between wood surfaces. These sprays contain fine particles of lubricant that adhere to the wood surfaces without leaving a greasy residue. Apply dry lubricant sprays sparingly to the contacting surfaces and allow them to dry completely before use. These products are ideal for use on drawers, door tracks, and any other wooden surfaces that require smooth movement.

In addition to their lubricating properties, dry lubricant sprays also offer protection against rust and corrosion. This makes them a great choice for outdoor furniture or tools that are prone to moisture exposure. By using these sprays regularly, you can prevent wear and tear on wooden surfaces and extend their lifespan.

10.Regular Maintenance and Inspection:

Regular maintenance and inspection are essential for preserving smooth wood-on-wood sliding action over time. Clean the wood surfaces regularly to remove dust, debris, or buildup that can impede sliding. Inspect drawer slides, glides, or other hardware components for signs of wear or damage, and replace them as needed to ensure optimal performance. Additionally, periodically lubricate the wood surfaces with a high-quality wood wax or oil to reduce friction and keep the wood in good condition.

In addition to regular maintenance and inspection, there are also some specific steps you can take to prolong the lifespan of your wooden furniture. These include avoiding direct sunlight and extreme temperatures that can cause warping or fading, using coasters or placemats to protect the surface from spills and scratches, and using felt pads or furniture glides on the bottom of objects to prevent them from scratching or damaging the wood.

Conclusion

In conclusion, mastering the art of making wood slide on wood is essential for various applications, from furniture construction to woodworking projects. By understanding the principles of wood friction and selecting suitable wood types, individuals can achieve smooth sliding surfaces that enhance functionality and ease of use.

Through proper preparation, including cleaning and sanding, and employing effective lubrication techniques, such as dry or wet lubrication, woodworkers can minimize friction and ensure seamless sliding action. Regular testing and adjustments allow for fine-tuning the sliding action to achieve optimal performance. Hopefully, this article gave you some helpful tips about how to make wood slide on wood successfully, so now that you have the proper knowledge on how to get the job done, why not give it a try today?

About the Author

Adrian Green, a lifelong woodworking enthusiast, shares his passion for the craft through The Woodenify Blog. With a foundation built on years of hands-on experience in his father’s woodworking shop, Adrian is dedicated to helping others learn and grow in the world of DIY woodworking. His approach to woodworking combines creativity, practicality, and a deep appreciation for the art of building with your own hands. Through his blog, he inspires individuals of all skill levels to embark on their own woodworking journeys, creating beautiful, functional pieces of furniture and décor.

Professional Focus

- Specializes in DIY woodworking projects, from furniture to home décor.

- Provides step-by-step guides and practical tutorials for woodworkers of all skill levels.

- Dedicated to helping readers build confidence and skill through easy-to-follow instructions and tips.

- Passionate about fostering a community of makers who can share, learn, and grow together.

Education History

- University of Craft and Design – Bachelor of Fine Arts (BFA) in Woodworking and Furniture Design

- Woodworking Apprenticeships – Extensive hands-on training with skilled craftsmen to refine carpentry and furniture making techniques.

- Online Courses & Masterclasses – Continued education in advanced woodworking techniques, design principles, and specialized tools

Expertise:

- DIY woodworking, carpentry, furniture making, and home décor projects.

- Creating accessible tutorials and guides for beginner to advanced woodworkers.

- Sharing the joys and satisfaction of woodworking, from raw materials to finished products.